A1 Bridging model systems to real catalysis: oxidative methane coupling

The direct oxidative coupling of methane (OCM) to C2-hydrocarbons (ethane and ethene) is a reaction of high interest, as it could greatly enhance the sustainability of the petrochemical feedstock for energy and matter conversion. However, this high-temperature process (T = 700-900°C) is characterized by low yield and poor selectivity towards ethene, thereby preventing its economical use at present. However, profitability will change drastically concomitant with the inevitable shortage of non-renewable resources. In addition, the current wasteful practice of flaring methane accounts for some 20% of total greenhouse gas emissions.

Although, the oxidative coupling of methane (OCM) is already widely studied by other research groups, the interplay of numerous surface-confined and gas phase reaction steps in this highly complex process is not yet understood. It represents an enormous challenge for the comprehensive analysis of the catalytic mechanisms in hierarchically organized environments.

Research goals

- Elucidation of the molecular mechanism of OCM including the identification of active sites and of the reactive species. This will be achieved by combining experimental and theoretical model studies on well-defined surfaces and gas-phase systems with in situ studies at ambient pressure.

- Comprehensive kinetic and mechanistic description of OCM at all relevant time and length scales from model systems to the miniplant level. This will be done in collaboration with Research Field C3 and include comparision of various reactor type (Research Field C4).

Results/Achievements

|

To elucidate the overall mechanism for the direct oxidation of methane to ethylene, Li-doped MgO has been chosen as the least complex catalyst from a long list of multi-component oxides. Moreover, with the Lunsford mechanism, a widely accepted model was available which considered Li-stabilised O-radical anions as active sites, and as key elementary step the formation of methyl radicals, which desorb into the gas phase for subsequent reactions. To unravel the complex structure-activity relationships of Li-MgO, a generic approach was applied focusing on different length-scales within a hierarchy of model systems.

The UniCat approach, therefore, was based on interconnecting gas phase models (MgO and Li-MgO gas phase clusters),[1-3] surface models,[4, 5], and materials synthesis.[5, 6] A variety of experimental and theoretical approaches has been used (i) to analyse the structural and thermodynamic properties of the species involved[3-5] as well as the dynamics of the individual reactions steps,[1, 2] and (ii) to describe the kinetics of the complex process.[7, 8]

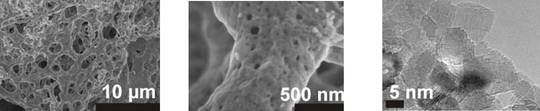

As one of the most important and quite unprecedented results, it could be demonstrated that Li is not directly required for the activation of methane,[5] but mainly functions as a promoter for inducing structural changes in MgO, specifically surface structural defects such as low-coordinated O2- ions. Structural studies of series of Li-MgO systems revealed that high-energy sites and defects are generated upon segregation and evaporation of LiOH, leading to structural promotion of MgO [4, 5]. The high-energy sites are subject to substantial restructuring under the aggressive reaction conditions leading to extensive catalytic deactivation that has been rarely studied so far.

Combining our results we arrive at the following description of the OCM reaction: The main process is a network of gas-phase reactions initiated by radicals such as CH3 or OOH species. At elevated pressures the gas-phase reactions lead to sizable yields and conversions even without catalyst. At ambient pressure, a catalyst is needed to inject activated species into the gas-phase process, whereby the catalyst must not generate electrophilic oxygen to prevent consecutive oxidation of the C2 products.

From a statistical analysis of 2700 publications addressing a large number of different catalytic systems that vary considerably in chemical composition, it has been deduced that the heterogeneous reaction occurs through homolytic activation of methane and dioxygen. The catalytic materials include either redox-inactive compounds or strongly modified redox-active oxide mixtures with more than three cations.

The performance of a pure MgO based catalyst is rather limited at steady state after several hundred hours of operation through a water-induced restructuration which removes a large number of surface defects responsible for reactivity. The nature of these surface defects will be identified and the studies expended to more complex model systems. However, in view of the lack of low long-term stability, pure MgO catalysts will not be used for reactor studies in the mini-plant.

Instead, among the various OCM catalysts, we have chosen the high-performing Na2WO4/Mn/SiO2 catalyst system for kinetic studies in the mini-plant. Both a homemade version and an industrial catalyst (BASF SE) showed high performance and stability under net oxidising conditions. The system restructures in part reversibly at operation conditions into a mixture of ternary phases with different structures that are only poorly active in combustion catalysis.

Most important publications

[1] S. Feyel, J. Döbler, R. Höckendorf, M. K. Beyer, J. Sauer, H. Schwarz; Activation of methane by oligomeric (Al2O3)n+ (n = 3, 4, 5): the role of oxygen-centered radicals in thermal hydrogen-atom abstraction; Angew. Chem. Int. Ed. 2008, 47, 1946-1950.

[2] K. Kwapien, M. Sierka, J. Döbler, J. Sauer; Reactions of H2, CH4, C2H6, and C3H8 with [(MgO)n]+ clusters studied by density functional theory; ChemCatChem 2010, 2, 819-826.

[3] K. Kwapien, M. Sierka, J. Döbler, J. Sauer, M. Haertelt, A. Fielicke, G. Meijer; Structural diversity and flexibility of MgO gas-phase clusters; Angew. Chem. Int. Ed. 2011, 50, 1716-1719.

[4] E. Finazzi, C. Di Valentin, G. Pacchioni, M. Chiesa, E. Giamello, H. Gao, J. Lian, T. Risse, H.‑J. Freund; Properties of alkali metal atoms deposited on a MgO surface: a systematic experimental and theoretical study; Chem. Eur. J. 2008, 14, 4404-4414.

[5] P. Myrach, N. Nilius, S. V. Levchenko, A. Gonchar, T. Risse, K.-P. Dinse, L. A. Boatner, W. Frandsen, R. Horn, H.‑J. Freund, R. Schlögl, M. Scheffler; Temperature-dependent morphology, magnetic and optical properties of Li-doped MgO; ChemCatChem 2010, 2, 854-862.

[6] S. Heitz, J.-D. Epping, Y. Aksu, M. Driess; Molecular heterobimetallic approach to Li-containing MgO nanoparticles with variable Li-concentrations using lithium-methylmagnesium alkoxide clusters; Chem. Mater. 2010, 22, 4563-4571.

[7] R. Horn, O. Korup, M. Geske, U. Zavyalova, I. Oprea, R. Schlögl; Reactor for in situ measurements of spatially resolved kinetic data in heterogeneous catalysis; Rev. Sci. Instrum. 2010, 81, 064102 [6 pages].

[8] S. Matera, K. Reuter; First-principles approach to heat and mass transfer effects in model catalyst studies; Catal. Lett. 2009, 133, 156-159.

Project team and expertise

| Prof. Dr. Klaus-Peter Dinse (FU Berlin) | High-Frequency EPR spectroscopy |

| Prof. Dr. Hans-Joachim Freund (FHI) | Surface science, thin films on supports |

| Dr. Raimund Horn (FHI) | Gel combustion synthesis High temperature reactivity studies |

| Prof. Dr. Gerard Meijer (FHI) | Gas phase IR spectroscopy |

| Prof. Dr. Joachim Sauer (HU Berlin) | DFT and ab initio methods, Hybrid QM/QM methods |

| Prof. Dr. Helmut Schwarz (TU Berlin) | Gas-phase ion chemistry |

| Dr. Maria Schlangen (TU Berlin) | Mass spectrometry |

| Dr. Marek Sierka (HU Berlin) | Genetic algorithms for gas phase clusters and surfaces, DFT method development |

Former team members | |

| Prof. Dr. Matthias Driess (TU Berlin) | Metalorganic chemistry; Precursor synthesis |

| Prof. Dr. Matthias Scheffler (FHI) | Density-functional theory, first-principles statistical mechanics |

| Prof. Dr. Robert Schlögl (FHI) | Molecular beam mass spectrometry |

| Dr. Karsten Reuter (FHI) | First principles statistical mechanics and kinetic Monte Carlo |

Prof. Dr. Martin Wolf | Ultrafast laser spectroscopy of surface reaction dynamics |